Silage, haylage and silage are succulent feeds that are prepared from green mass (grass), stored under anaerobic conditions (in trenches, towers, mounds) and serve as a replacement for green feed in the winter. These are the main feeds in dairy farming now and they can reach up to 80% of bulk feeds in the diet.

Silage is a succulent feed prepared from green mass and stored under anaerobic conditions due to the formation of organic acids as a result of lactic fermentation. The moisture content of the silage according to GOST 55986-2014 is more than 70%. Low pH of silage 3.8-4.2 is the main preservative factor

Haylage is a succulent feed prepared from green mass and stored under anaerobic conditions due to the physiological dryness of the raw material (silage humidity is (40) 50-60%. The formation of carbon dioxide as a result of plant respiration is an additional preservative factor.

The term silage is relatively new to our feed production. The fact is that silage is dried silage or haylage with high humidity. According to GOST 55986-2014, silage is silage with a moisture content of 60-70%.

Silage, haylage, hay

For cattle owners, the spring period is preparation for the preparation of grass feed. Important considerations include the type of feed, how it is stored, nutritional content, palatability and cost.

Cattle consume fibrous plant material using hydrolysis of simple carbohydrates and other nutrients in the stomach, and microbial fermentation of complex carbohydrate sources in a uniquely adapted hindgut. Energy derived from fibrous plant material comes from the fermentation of carbohydrates such as cellulose, naturally occurring microbes found in the cow's hindgut.

Fermentation of these carbohydrates results in the formation of short-chain fatty acids called volatile fatty acids. They are used by animals as an excellent source of safe energy.

In summer, it is easy to provide cattle with fresh feed on pastures. The weather in Russia does not allow the use of pastures as a feed source for most of the year. For the rest of the year, cattle owners need to prepare high-quality forage - hay, silage and haylage.

Recent comments

- admin to the post rating of Crimean cognacs 2021

- Yuri Georgievich on rating of Crimean cognacs 2021

- admin to the entry the better way to wash dishes with a sponge or rag

- Nikita on what is better not to ask Alice

- Olga on the post: Recommend a good fortune teller in Krasnodar

© 2022. Product rating - TOP 10.

All rights reserved. Attention! The information published on the site is for informational purposes only and does not constitute a recommendation for use. The Materials may contain information intended for users over 18 years of age. 18+

Feed preservation methods

Feed for cattle is most often prepared in the form of hay, haylage or silage. The first step in preparing any type of forage for preservation is cutting and then drying the grass with sun and air while it lies in the field. As feed dries out, the moisture level drops and the percentage of dry matter increases. The amount of moisture present in the feed when drying will determine whether the feed is stored in silos, hay bales or silage.

The first step in preparing forage for preservation is to cut it and let it dry in the sun in the field. When bales are formed, the amount of moisture in the feed determines whether it is stored as silage or hay.

Difference between hay and haylage

Definition

Hay: Grass that has been cut and dried for use as feed

Silage: Grass is compacted and stored in sealed conditions in a silo without pre-drying.

Moisture contents

Hey: 12%

silage: 40-60%

DM value

Hey: 82%

silage: 40-60%

Preparation

Hay: Grass is cut and dried in the field

silage: Grass is cut and tightly packed to encourage microbial activity

Storage

Hey: Like a bale

Silo: Bales covered with polyethylene film

digestion

Hey: Not digestible

Silage: Partially digestible; easily digestible by animals

Conclusion

Hay is dried grass with a moisture content of up to 12%, and silage is fermented grass with a moisture content of up to 40-60%. Therefore, the main difference between hay and silage is moisture.

Link:

1. “Hay, haylage and silage: what’s the difference?” Horse Magazines

October 27, 2022

What defines hay?

Fresh grass when cut usually has a moisture content of at least 80%, which equates to a dry matter of 20% or less. Cut forage intended for hay must be field dried to a moisture level of no more than 12 percent. A baler that produces rounds or bales with a moisture level greater than 12 percent will cause them to become heavier and risk mold and heat infestation. Heating can occur because the presence of sufficient water in the feed allows metabolic activity to continue, causing heat to build up in the bale or bale. The heat can become so high that the hay spontaneously combusts and fires occur in the storage area.

Typically, bales and rolls of hay are wrapped with hay twine or netting.

Harvesting techniques at home

In order to obtain high-quality silage for cows, it is necessary to correctly calculate the timing of collecting plants for processing, correctly build a hole or trench, which is much more affordable and easier than buying an expensive silo tower. Plants must be mature, but not dry, otherwise it will not be possible to obtain a sufficiently nutritious product.

Plants that are too green will produce a lot of juice; it will be difficult to compact them tightly, which will lead to air entry, fermentation, and mold development. Dry products are hard and do not have high nutritional value for cows and cattle.

This primarily concerns corn silage. The grain and its tops do not ripen at the same time. For maximum quality and nutritional value, the grain should be ripe, and the stems and leaves should still be green and sufficiently juicy. It is believed that for feeding domestic animals and dairy cows in particular, silage prepared not in the summer, but after the onset of the first frost, is best suited.

A silo with a capacity of 2 cubic meters is made per cow. Most often it has a concrete bottom and the same or brick walls. Sides 20-30 centimeters high are made above the ground. They prevent water from entering the silo container. In summer, the pit can be used to store irrigation water, and before loading the silo, it must be dried and the walls whitened with lime.

See also: What ways can you increase milk production from a cow at home? Read

A layer of dry leaves collected from the orchard is placed at the bottom of the pit, then layered with dry hay up to 10 centimeters thick. After this, waste from your own garden and vegetable garden is placed in the pit, including rejected small fruits, tops of root crops and the plants themselves, for example, small carrots and beets that are not suitable for storage and eating. Pumpkin vegetables chopped into pieces, sunflower remains along with baskets, corn stalks and cobs, cabbage, and so on are also placed there.

The prepared juicy mass is chopped directly in the pit with sharpened shovels with a straight cutting edge. Thanks to this processing, the mass is crushed and compacted. A “cushion” of dry leaves and hay placed on the bottom prevents damage to the bottom of the silo pit during such treatment.

Expert opinion

Zarechny Maxim Valerievich

Agronomist with 12 years of experience. Our best country expert.

Ask a Question

After the layer of chopped vegetables and tops rises to 40 centimeters, 1 kilogram of table salt is scattered over its surface. If there is a lot of liquid in the mass, dry hay or dried leaves or dried tops are added to it.

It is important to compact the silage evenly, especially in corners where air pockets may remain. Corner areas are carefully pounded with wide sticks or tampers. The prepared silage is covered with apple leaves on top, covered with plastic film and covered with a layer of earth so that there is no air left under the tire.

The next step is to create a roof and insulate the silo pit. To do this, it is covered with boards, strengthened with stones so that it does not blow away with the wind. Then cover the container with a thick layer of plant residues that cannot be used for livestock feed. From above, the entire structure is once again covered with durable, waterproof material, for example, roofing felt, roofing felt or slate sheets.

See also Top 14 methods of slaughtering livestock and technology for cutting up carcasses at homeRead

Differences between haylage and silage

Forage harvesting is the practice of packing dried or fresh grass into an anaerobic environment in which there is no oxygen. The saturation process allows natural microbes in the grass to ferment natural sugars (water-soluble carbohydrates) into organic acids such as lactic acid or acetic acid. As acids accumulate in the packaged feed, the pH level drops, eventually reaching a point where there can be no more microbial activity. This process usually takes about 21 days. When the pH stops falling, the feed is considered stable and ready for storage. To eliminate air from feed intended for storage, bales of haylage are usually wrapped in agrostretch film, and the silage is placed in silo pits and covered with silage film.

Forage bagged too wet cannot reach a low enough pH through the fermentation process and is therefore much more susceptible to spoilage and nutrient loss than dry bales. The result may be less desirable fermentation end products. An example of this is wet round bales that have a buildup of butyric acid rather than lactic acid as the end product of fermentation. Butyric acid does not have as low a pH as lactic acid and therefore does not preserve feed. It also has an unpleasant odor.

Feeds that are heavily dried are not compact enough to exclude all oxygen, allowing aerobic (metabolic activity that requires oxygen), microbial activity, and just like regular hay bales that are dried to more than 12 percent moisture, to be released heat. Feed that is bagged too dry is a fire hazard and can result in poor feed quality due to heat in the bale.

The difference between haylage and silage is the moisture content. In general, haylage has a moisture content of 15 to 40 percent, while silage has a moisture content of more than 40 percent. In silage with a higher moisture content, feed retention occurs as a result of the fermentation of sugars in the grass under anaerobic conditions. This leads to a drop in pH. In general, good silage in a silage trench should have a pH of less than 5. The pH of silage in a round bale will be above 5 on the pH scale of 14. The retention of feed in the bale is due to the low moisture content, which inhibits the growth of microorganisms.

Difference between hay and haylage

main difference

between hay and silage is that

hay is cut and dried for use as animal feed, while silage is fermented green feed stored in a silo.

The moisture content in hay is no more than 12%, and in silage - 40-60%.

Hay and silage are two types of crops that are used to feed livestock during the winter since they cannot graze the fields during this period of time. Both crops consist of grass. They can be considered as methods of preserving feed.

Key areas covered

1. What is Hay - Definition, Facts, Treatment 2. What is Silage - Definition, Facts, Treatment 3. How Are Hay and Silage Similar - Common Features Outline 4. What is the Difference Between Hay and Silage - Key Differences Comparison

Basic conditions

Fermentation, Grass, Hay, Microbes, Moisture Content, Silage

1.How to ensile a specific crop/mixture of crops?

Experts ask how to prepare:

- Sudan grass silage

- pea haylage

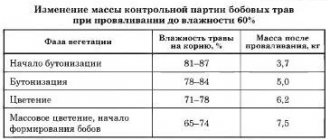

- haylage from leguminous grasses (clover and alfalfa)

- haylage made from vetch-oat or pea-oat mixture

- sunflower silage

- silage from crops growing in northern regions

- corn silage

- alfalfa silage

- silage made from a mixture of sunflower and soybeans

- barley haylage

- cruciferous silage

- silage from drought-resistant crops

- corn grain

- beet pulp silage

There are a huge number of different variations of forage crops that can be canned. Some of them are easy to ensile, others are much worse. Moreover, the same crop/combination of crops will have different fermentation abilities

.

Therefore, no matter what crop you are going to ensile, it is important to learn how to determine what combination of dry matter and nutritional values should be in the green mass in order for fermentation conditions to be optimal. Having mastered this skill, a specialist will be able to make operational decisions (for example, the moment of mowing, the degree of wilting) aimed at improving the properties of the mass for fermentation, regardless of which crop or mixture of crops is being ensiled.

How to determine the ability of different crops to ferment and calculate the fermentation coefficient is explained in detail with examples by Dr. Andreas Milimonka in the second lesson of the training course “Making silage and haylage” - this information is already available for study, so if it is important for you to understand, welcome to the course ! .

Also, read more about the features of silage of various crops in these articles:

Harvesting alfalfa for silage

Making corn silage

Tips for ensiling grass silage

Canning Wet Corn Grain

Beet pulp silage

How to choose a preservative for feed silage?

- What are the types of preservatives?

- Which is better - biological or chemical?

- What are the differences between different forms of preservatives: liquid, dry, organic?

- How to combine different forms of silage aids?

- How to calculate dosages and do they need to be changed depending on different cuttings?

In order to learn how to select preservatives, first of all you need to understand once and for all what processes take place in the silage trench after it is covered and what exactly influences the way the silage turns out. Dr. Milimonka talks about this in lesson 6 of the course “Preparing silage and haylage.”

And the 7th lesson is devoted to consideration of issues when funds are needed for silage. How their different types help to compensate for the shortcomings of the silage crop or technology and gives a simple algorithm for selecting additives. Having studied this information, it is much easier to communicate with representatives of commercial companies, and also make a choice in favor of specific products.

Scientific basis of canning succulent feed

The main points important for understanding are presented in the form of a presentation. It can be enlarged to fill the entire screen.

Silage and haylage are stored anaerobically in trenches or towers. Technological methods for preparing these feeds are virtually the same:

- mowing green mass (grass);

- drying (depending on the type of feed, the final moisture content will vary);

- selection and transportation to the storage location;

- tamping;

- hermetic shelter of a filled storage facility.

Thus, the final product will depend on the raw material - whether it can be ensiled or not and the moisture content of the mass being laid.

What is the optimal technology for making silage and haylage?

There are also a lot of questions in this block. But first I want to share the opinion of our subscriber:

“When harvesting, everything is just as important - this includes preparing the trench for silage, patching potholes and holes between concrete slabs - after all, the majority of people still use trenches from the Soviet period. And tamping, and all its stages - how to start tamping, how to finish it. But what “kills me” most of all is when you come to take samples and see that the mass seems to be good, and the tamping is more or less, but the edges of the trench are not closed, the mass was brought a little too little, and when it “sank”, then the middle turned out “trough”, and, taking into account the fact that many farms “save money”, they do not lay a thin film along the edges, and the black one falls off the edges of the trench and rainwater floods over it, then the work of agronomists and machine operators is devalued by this elementary negligence and unfinished work. ."

Here are some questions from this block:

- What should be the geometry of silo trenches, the optimal ratio of length and width, what is better, making them longer or wider?

- Are there any guidelines for the time of compacting silage and haylage, how does it depend on the incoming volume, the minimum and maximum daily tonnage?

- The problem is that if we harvest haylage straight from the field, there is high humidity, if we mow and wither it, then we collect it from the field with soil and clostridia, is there a “golden mean”? And how to navigate here?

- How to manage and motivate staff during procurement work?

Lesson 3 of the course “Basic operations for making silage in the field” and lesson 4 “Basic operations for making silage in a trench” are devoted to these issues, as well as a large master class by Vladimir Mirnenko “Field work as an important stage in obtaining high-quality haylage” (more than 4 hours of practical advice and life hacks). These lessons are a good way to train the entire team of personnel involved in the silage process.

Quality assessment and storage of silage and haylage

Specialists are interested in scoring the quality of basic feed, quality criteria, and what to do if the feed is already of poor quality, but needs to be fed.

There are also deeper questions, such as these:

“I think that today the most pressing and unexplored issue is the issue of analyzing the received feed. Today, many foreign laboratories, for example Eurofins Agro, do analyzes of feed, soil, etc.

Nobody knows how to read them and use them correctly in their work.

It is also important to talk about quality criteria: what do you think are the most important in the analysis? From here “legs will grow” - about the next dialogue - cutting height, cutting frequency (some people say they get 3-4), fertilizing and so on...”

Answers to basic points regarding this block of questions are given in these articles:

Silage storage and quality

The Silage and Haymaking course takes an in-depth look at the processes that occur in a silage trench after it is opened and stored and how they can be influenced. Issues of economic efficiency are also raised.

And I also wholeheartedly recommend a week-long advanced training course in Germany “Feed Production and Feed Evaluation.” There is a separate block dedicated to the issues of feed analysis and evaluation - very interesting and useful! I checked it myself!

And, of course, there are a number of questions that have yet to be answered!

Dear reader, do you now have questions about making silage and haylage? Please write them in the comments!

Operating principle of a rotary sensor

When loading cement, the following occurs:

- Turning on the electric motor - the shaft with the blade begins to rotate at low speed. Torque from the shaft is transmitted to the sensor shaft.

- Filling the container to the sensor level - the blade enters the cement mass. Since the engine power is low, the “flag” gets stuck in the cement and stops rotating.

- Closing the switch in the sensor control system with a signal sent to the control panel and an audible warning. In this case, the engine automatically turns off.

When unloading, the process occurs in reverse order:

Read also: What is hardware facial resurfacing?

- The blade is released from the cement.

- The spring is activated, opening the switches.

- Power is supplied to the motor, and a signal is sent to the control panel that the level of the contents of the container has decreased.

Even completely dry cement tends to quickly stick to the walls of the container and cake. This has a bad effect on the properties of the material and interferes with unloading - after 1–2 days the binder “refuses” to move to the outlet when the shutter is opened. The problem is solved by including vibration shaking systems (vibrating pan or industrial vibrators) or aeration into the package.

Vibrators contribute to the gradual destruction of the silo; the vibrating pan and aeration systems do not have this drawback. Due to the low price, preference is usually given to an aeration system.

Haylage. Technology for preparing highly nutritious feed

In fact, haylage is an intermediate link between hay and silage and is an effective feed source for cattle, which allows domestic animals to safely survive the long winter period.

Haylage contains less moisture (fifty to sixty percent) than silage, which reaches seventy percent moisture content, but retains almost three times more dry matter.

The main preservative factor of dried plants is not acidity (as happens when making silage), but the physiological dryness of the environment, therefore acid formation in haylage is limited and its pH

" is only about five units.

At the end of the grazing season, when the animals are kept in a stable period, haylage makes it possible to provide livestock with a nutritious and high-quality diet, since its feed value is quite high and is equal to fresh greens. Haylage can be called a kind of high-quality “canned food” in the form of dried grass, which has a pleasant, slightly sour aroma.

Advantages of haylage compared to silage

Cattle (as well as sheep and goats) consume haylage much more readily than silage. At the same time, this product is better absorbed and contains a large amount of beneficial nutrients.

Haylage has a pleasant rich hue (emerald yellow if it is based on cereal grasses or brownish-greenish when prepared from legumes or legume-cereal plants).

Preliminary drying of plants leads to a decrease in their moisture content (about five hundred kilograms per ton of raw material), which subsequently helps reduce the risk of feed freezing (for example, when laying silage, about seven hundred kilograms of moisture usually gets into the trenches, which increases the risk of freezing).

It should also be noted that the preparation of haylage and its “preservation” does not occur due to the process of fermentation of organic acids, as this usually occurs during the process of ensiling plants, but due to the physiological dryness of the environment in which crops dry naturally. This method of canning ensures better preservation of beneficial nutrients, especially sugar and protein.

In addition, the process of drying plants itself requires significantly less time, and therefore it is not so dependent on the weather and, under favorable conditions, can take no more than one or two days.

Typically, haylage is prepared from leguminous grasses (clover, alfalfa, sainfoin), but annual and perennial grasses and cereals can also be used for its preparation, and it should be remembered that young plants have a stronger odor and have increased nutritional value.

In this case, legumes should be mowed in the “budding” phase, and cereals at the beginning of heading.

Rough-stemmed, rigid plants, as well as corn and sunflower, are unsuitable for producing high-quality haylage.

The silage harvesting technology usually consists of several stages:

· Crush (legume) plants to speed up drying

· Drying and raking plants into windrows

Tedding (turning) the grass

· Grinding of harvested crops

Silage feed - a complete guide from an expert

Andrey Medvedev, livestock specialist at MATRITSA, talks about the advantages and disadvantages of silage feed

Silage feed, both in the past and today, is the mainstay in dairy farming in the Russian Federation, the USA, Western Europe and many other countries of the world. They are harvested in tens of millions of tons per year. They often make up a large proportion of the volume of feed in the diet and at the same time guarantee volumetric saturation of the rumen of ruminants. Traditionally, through silage feed, the farmer tries to give the cow the maximum amount of energy, nutrients and biologically active substances. This is due to the fact that the cost of silage and haylage is significantly lower than the cost of other types of feed.

What plants can be ensiled

It is believed that the ability of plants to make silage depends on the amount of sugar in them and the moisture content of the forage. However, given the same sugar content, different plants ensile differently if they have different buffer capacity. An indicator of the suitability of plants for ensiling is the ratio of the amount of sugar in them to the buffer capacity. Since the buffer capacity is significantly determined by protein substances, the ratio of sugar to crude protein can be considered a criterion for silage. If this indicator is 1 or more, then the plants ensile well. From 0.6 to 0.9 – silage will take place at an average level. And less than 0.6 - the process will be difficult. For example, in corn the indicated ratio is in the range of 1.3 -1.4 and the success of its ensiling is beyond doubt. Green fodder oats have a sugar to protein ratio of 0.91, which is average. While legumes (clover and alfalfa) are distinguished by a clearly insufficient value of 0.26 and 0.17. Their ensiling without additional measures, such as the introduction of preservatives into the ensiled raw materials and other similar methods, is unlikely to be successful.

The principle of making silage

The principle of making silage is the ability of lactic acid bacteria to convert the sugars of feed raw materials into lactic acid. This requires anaerobic conditions (the absence of oxygen in the mass), which provide an advantage in the development of lactic acid and acetic acid bacteria. The gradual accumulation of these acids helps to reduce the pH of the plant material. This happens in three stages.

First stage

- heterofermentative fermentation. It takes about 10 days. During which various microorganisms present in the silage mass develop. During this time, all oxygen reserves are quickly consumed here and optimal conditions are created for the development of anaerobic microbes.

Second phase

silage maturation is a period of homofermentative fermentation. It also lasts about 10 days, but is characterized by the massive development of lactic acid and acetic acid bacteria. The active acidity of the medium decreases to the standard value (pH = 3.8-4.2).

Third stage

– death of lactic acid bacteria. Over the course of 10 days of the third stage, the release of acids into the feed mass becomes such that the existence of any microorganisms is no longer possible. That is, the silage microflora dies under the influence of its own metabolites.

In total, the ripening process of silage feed lasts approximately 30 days, after which they become suitable for feeding.

Classic silage technology

First period

making silage means mowing the forage mass. It is advisable to mow plants during those phases of the growing season when the sugar content in them is maximum. For corn (the standard silage crop), this phase of the growing season is milky and milky-wax ripeness, for sunflower it is the early stage of flowering. Harvesting is carried out using forage harvesters, which can be either trailed or self-propelled.

Second period

– grinding the silage mass to a size of no more than 4-5 cm. Modern technology makes it possible to obtain a grinding size of up to 1 cm or less. After the combines cut the corn, it is fed into the grinder. The resulting crushed silage mass is loaded into a tractor trailer or truck body.

Third period

– transportation of the silage mass to storage.

The fourth period

– laying silage in storage, which must be organized in a short time. If you drag out time and do this for more than 4 days, then, under conditions of constant oxygen supply, oxidative processes will begin. The silage will heat up and darken, losing its beneficial properties.

Fifth period

– compaction of the mass in the silo storage in order to completely displace air from the silage mass. Tractors with blades level the brought mass evenly over the trench. Compaction is carried out by heavy tractors, which, passing along the entire trench, compress the green mass

Sixth stage

– covering the silo with insulating material.

Features of silage preparation

Until now, polyethylene remains the most widely used material for covering silos from the unwanted effects of moisture and oxygen.

The film must be sufficiently stretched over the surface of the silo. It must be placed under the edges of the sides of the storage facility to a depth of at least 0.5 m. Its reuse is not allowed. In the USA and Western Europe, and in recent years in the Russian Federation, silage in polymer bags using special pressing equipment and preservatives is becoming increasingly common. It should be noted that this advanced technology makes it possible to ensile not only plant matter, but also grain. Due to this, it is possible to significantly reduce the cost of drying it and retain more energy and nutrients in the grain.

The most progressive method of making silage today is considered to be packaging plant mass in plastic film in the field, immediately after mowing, chopping and compacting. Indeed, this method allows you to avoid most mistakes in the process of making silage from all types of feed raw materials. At the same time, it is necessary to note that in production conditions typical for the CIS countries, its use is greatly limited by the condition of field roads. In most cases, if the condition of the roads leaves much to be desired, then it is virtually impossible to avoid damage to the integrity of the polyethylene film during transportation. The consequence will be a decrease in the quality of silage, the cost of which when harvested using this method is quite high.

The most common violations of silage making technology

Mowing plant mass at inappropriate phases of the growing season.

In production conditions, the quality of silage raw materials is often neglected in order to increase the volume of feed harvested. As a result, the plants are kept in the field, after which the amount of sugar in them is significantly reduced, and the release of lactic acid into the silage mass becomes insufficient to ensure its self-preservation.

For example, the sugar content in the green mass of corn in the early flowering phase is 2.08%, in the flowering phase of plants - 2.66%, in the milky-waxy ripeness phase of the cobs - 3.08%, and in the early waxy ripeness phase - 3.24%. However, after the cobs ripen, the sugar content in corn for silage decreases by more than half, which greatly complicates the ensiling of plants and deteriorates the quality of feed. A similar picture is also observed when trying to ensile feed with insufficient sugar levels. A way out of this situation may be the use of chemical preservatives (preparations based on propionic, formic, benzoic acids) and a number of homofermentative and heterofermentative bacterial cultures. This approach to silage conservation can reduce its losses during harvesting and storage by 2-3 times.

Errors in the amount of plant chopping when storing for silage.

Here there is usually a conflict of industrial and biological interests. On the one hand, modern silage harvesting equipment makes it possible to ensure a plant chopping value of 0.5 -1 cm, at which the maximum degree of compaction of the silage mass in storage can be obtained. Feed preparation specialists are usually interested in such an approach. However, on the other hand, livestock specialists note that the minimum size of silage particles does not allow obtaining a layer-by-layer ratio of rumen content fractions that is most favorable for the physiological state of the animal. The consequence is disturbances in chewing gum processes, minimal salivation and a tendency to acidosis, which gradually becomes chronic.

Long and uneven placement of silage mass in storage.

It is generally accepted that at least 1 m of raw material in height must be laid per day along the entire perimeter of the silo storage. In this case, the storage can be filled in 4-5 days, which will ensure high feed quality. It is a mistake to try to increase the height of storage by adding additional blocks on top. This technology often ends in problems, because additional blocks at high altitudes do not have sufficient stability, especially in the winter.

As a modern, profitable and practical option, one can consider laying silage on small asphalt-paved areas, which are located next to cattle premises. The process of storing the silage mass in storage in this case is as efficient as possible, and the cost of transporting feed is minimized.

Insufficient compaction of silage raw materials.

There can be many reasons for this, starting with a trivial lack of silage harvesting equipment during the forage harvesting season, and ending with low humidity of plant materials, as well as too large a particle size. In this aspect, the most effective option for making silage can be called making it in towers, where compaction occurs under the influence of the own mass of the ensiled plants. However, this method can also be called the most expensive, because the construction of technologically advanced silo towers is expensive, and their constant maintenance requires considerable financial resources.

Saving on material to isolate the silo from the environment.

An attempt to replace the polyethylene film used to isolate the silo from the outside air with straw or soil is usually accompanied by damage to the top layer of the silage mass to a height of 0.5 m or more. This approach to silage preparation results in losses that are tens of times greater than the benefits from saving on polyethylene film.

Disadvantages of silage as the main diet feed

Silage, as the main feed for ruminant animals, has been used for quite a long time. To date, technologies have been developed for preparing silages from various forage crops, both legumes and cereals. In principle, it is quite difficult to put legume plants into silage, because their sugar content is insignificant, but their buffer capacity is significant. The use of preservatives in this context expands the possibilities for silage, but any type of silage still has a number of disadvantages. In conditions of highly productive dairy cattle breeding, they force us to look for alternative options that level out the negative effects on the animal’s body when using large quantities of acidic feed in the diet. One of the practical solutions to this issue is the combination of silage and haylage in diets, which makes it possible to ensure acid-base balance both in the diet and in the body of cows.

How is haylage different from silage?

The technology for making haylage is very similar to making silage, but it also has some peculiarities. Firstly, for the preparation of haylage they use valuable raw materials of legume forage plants, the possibilities of ensiling are very limited. At the same time, the process of preparing haylage consists of the following stages:

— mowing grasses with flattening (for coarse-stemmed plants);

— drying in the field up to 50-55% with single or double turning;

- raking the dried mass into windrows;

— selection of grass from windrows, chopping and loading into vehicles;

— compaction of the mass into sealed rolls, bales or trenches;

- thorough compaction and sealing.

As you can see, the technology for making haylage differs from the technology for making silage only in that the silage mass is not withered in the field, but on the contrary, they try to preserve it with maximum moisture. At the same time, the very principle of haylage preparation has a completely different basis. By wilting the mass of plant material up to 45-55%, the effect of removing water from the intercellular formations of plants is achieved. At the same time, the possibility of development of the bulk of microorganisms in feed raw materials is limited. The force with which plant cells retain the moisture remaining in them (55-60 atm.) becomes greater than the suction force of microorganisms (50-55 atm.). However, it is precisely under such conditions that lactic acid bacteria gain an advantage in their development, preserving the haylage and reducing its pH to 5-5.5 units.

However, at this humidity, molds can still develop, the suction power of which reaches about 190 atm, but they need oxygen to live. That is why, to prevent molding of raw materials when harvesting haylage, the plant mass after drying is placed in anaerobic conditions. From a chemical point of view, silage and haylage differ in two main factors. The moisture content in silage reaches up to 70-75%, and in haylage – 45-50%. At the same time, silage is an acidic feed (pH = 3.8-4.2), and haylage is moderately acidic (pH = 5-5.5).

What is better in cow diets – haylage or silage?

When considering this issue, it is first necessary to address the economic side of the problem. Based on the fact that less expensive plant raw materials are used to make silage (corn as a reference), it can be argued that its cost will be lower compared to the cost of haylage. However, such a superficial assessment in conditions of highly productive dairy cattle breeding is unlikely to be correct. Factors in the analysis of diets for a number of indicators also play a role here, the total effect of which determines the acid-base balance in the animal’s body.

The efficiency of nitrogen use in the rumen of ruminants is also important for assessing silage and haylage diets. Rumen nitrogen balance is a measure of the nitrogen supply to rumen bacteria taking into account the energy contained in the feed. If the balance in the rumen is negative, this indicates a lack of nitrogen. In this case, microorganisms have a sufficient amount of energy at their disposal, but not enough protein. A negative RNB (Ruminant nitrogen balance) indicator shows how much nitrogen needs to be added to the diet to compensate for protein deficiency.

For example, such a trend in a separate specific case was observed with the silage-concentrate type of feeding of bulls (RNB = -19 g N/kg DM), where for optimal nitrogen balance it was necessary to add 19 g of nitrogen per 1 kg of dry matter of the diet. This issue can be resolved by switching from silage to haylage feeding, after which the nitrogen balance in diets becomes positive (RNB = 50.8 g N/kg DM). However, exceeding this indicator by more than 50 g N/kg DM can also cause metabolic disorders in ruminants (alkalosis, acidosis).

The balance of nitrogen in the diets of steers with a combined silage and haylage type of feeding, in our opinion, is the most optimal, and in this example the RNB value was 8.6 g N/kg DM. In this case, the ratio of all protein fractions with the metabolic energy of the diets will be the best among all the types of feeding proposed above. From this we can conclude that the most favorable type of feeding for cattle is still a mixed silage-haylage type of feeding.

Seasonal and uniform livestock feeding systems

Previously, a seasonal feeding scheme for dairy cattle was widespread. When green conveyor or pasture feed was used in the summer, and canned feed from storage facilities in the winter. In recent decades, this scheme has become less and less popular.

A number of technological problems are associated with the seasonal scheme:

— frequent change of feed in the structure of the green conveyor;

— the difficulty of balancing diets with constant differences in the chemical composition of feed;

— seasonal disturbances in the gastrointestinal tract of animals;

— sudden changes in weather conditions causing transport problems;

— insufficient provision of equipment during the harvest period;

— high level of negative influence of the human factor.

At the same time, the timing of harvesting forage crops is determined by the principle of the conveyor, but not by the maximum accumulation of nutrients in them. And the expectation of exploiting pastures throughout the entire grazing period is not justified in most regions of Russia.

An effective alternative to a seasonal feeding schedule for cattle can be feeding them canned feed throughout the year. The same type of system today is more progressive. With high milk yields of cows, this eliminates the above-mentioned problems of a physiological, technological and economic nature.

However, to ensure the efficiency of the uniform feeding scheme, it is necessary to prepare high-quality silage feed throughout the year. Diets for cows and young animals from canned feed should be prepared taking into account the acid-base balance, the level of protein breakdown in feed, the ratio of NDC and FDC, and the availability of starch. Only with such a scientifically based approach is the success of the uniform feeding system for dairy cattle guaranteed.

Author: Andrey Medvedev, [email protected]

MATRITSA company