The health and productivity of cows directly depends on their housing conditions. These include not only nutrition and daily care, but also maintaining cleanliness in the stalls. To make it easier to clean stalls, farmers use a variety of mattresses and bedding. They not only make cleaning easier, but also absorb odors and excess moisture. It is much more comfortable and warmer for cows to sleep on them than on a regular floor.

What to make a floor for a cow in a barn from

When choosing a material for construction, you should pay attention to its ability to retain heat, absorb or repel moisture, and ability to withstand loads. Equally important is the raw material used in the manufacture of the material: how toxic it is, and whether its fumes will harm the cows.

The advantages of a wooden covering are its environmental friendliness and the fact that it retains heat well. Otherwise, wood is not recommended for flooring, since it quickly absorbs moisture and odors; this property accelerates the aging process of wood and its rotting.

The tree may not support the weight of the herd; in addition, dozens of hooves will leave indentations on it, and subsequently the animal may trip here and be injured. Wood is difficult to disinfect and clean from feces, so the material also loses in terms of barn hygiene.

Cement or concrete

There are conflicting opinions regarding concrete and cement:

- on the one hand, the material is durable and strong, does not allow moisture to pass through, and is easy to clean, wash, and disinfect;

- on the other hand, concrete is cold, such a floor will provoke diseases in animals, in particular, mastitis in heifers, reducing their productivity.

However, after weighing the pros and cons, most farmers use concrete. The lack of heat is compensated with the help of warm bedding, for example, livestock mats.

Burnt brick

Brick is made from clay, which is then fired for strength, producing hollow and solid bricks without voids.

Among the advantages of the material:

- environmental friendliness;

- sound insulation;

- thermal insulation;

- fire resistance;

- resistance to corrosion and fungi.

The main disadvantage is considered to be the high cost compared to other materials; in addition, brick is not able to withstand heavy loads. The hooves will leave cracks and gouges, which over time will begin to let in moisture. Brick is more suitable for the walls of the structure.

Samana (unburnt)

The peculiarity of adobe is that clay and straw are used in its production. To give it completeness, it is not fired, but dried in the sun. The product is completely natural.

Advantages of adobe:

- low cost;

- heat and sound insulation;

- fire resistance;

- hygroscopicity.

Minuses:

- protection from dampness in the form of plaster is required;

- the material is susceptible to fungi and insects;

- questionable frost resistance in harsh winter conditions.

The table shows the performance characteristics of the described materials:

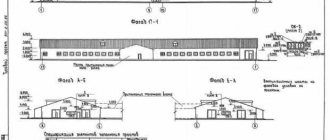

Requirements for the floors of barns and other premises of the dairy complex

Floors in stalls, boxes and cages for calves must be solid, level, non-slip, low thermal conductivity, resistant to waste liquid and disinfectants and waterproof.

The heat absorption rate of floor surfaces in animal resting areas should be no more than: young animals from 3-4 months of age for fattening - 15 W/(sq.m*°C), all other animals - 12 W/(sq.m*°C ).

Those that most fully meet these requirements and are recommended by SNiP for livestock buildings are expanded clay concrete floors monolithic or covered with slabs, floors with rubber bitumen coating on an underlying layer of expanded clay concrete, floors made of bitumen-expanded clay slabs. Wooden plank floors on joists embedded in adobe or concrete preparation are quite satisfactory in terms of technological requirements. When keeping animals on bedding, floors covered with heavy concrete are allowed.

In sections for group housing of livestock, as well as in manure passages, slatted floors made of reinforced concrete or cast iron gratings are used. The configuration of the slatted floor slats and the size of the gaps between them must ensure that excrement falls into the channel and does not cause damage to the limbs of animals. The planks must have a continuous working surface without bevels or roundings. It is advisable to choose the direction of the grid elements perpendicular to the direction of the main movement of the livestock.

There are no thermal requirements for floors in manure and feed passages, but here the floors must be of increased strength, since animals, manure removal mechanisms and feed dispensers move along these passages. Typically, floors in manure and feed passages are asphalt concrete, concrete, edge-brick or lattice.

The floors in the milking parlor, vacuum pump room, cow sanitation room, boiler room and other production premises are asphalt concrete, cement-sand and concrete. In laboratories, it is possible to install plank floors, and in dairy areas, from Metlakh tiles.

Floors in stalls, boxes and aisles must be located at least 200 mm above ground level. To ensure slurry drainage, the floor in stalls, boxes and manure passages is made with a slope of 1-2% towards the manure channels. Lattice floors and channels for removing manure by mechanisms are designed without a slope.

How to make a stall (barn, barn) for cows?

Cows are demanding in terms of living conditions, and the profitability of the enterprise, the health of the livestock, weight gain and the amount of milk depend on how comfortable and cozy the premises are. How to build a farm for cows so that it meets all the requirements for keeping animals and brings maximum income?

For good productivity, cows need a comfortable barn.

General principles of barn construction

Before starting construction, you will need to take into account some rules, namely:

- the location of the building is chosen taking into account the wind rose;

- the future farm should not be located near residential premises or water sources;

- the material chosen is high-quality, safe, with high thermal insulation;

- the project is drawn up taking into account heating, ventilation and lighting;

- The dimensions of the room must correspond to the needs of the animal; any movements should not cause difficulties.

Did you know? On the skin of the nose of the reproaches there are lines that are so similar to the pattern of human palms. They are unique, like prints, and are never repeated.

Primary requirements

Housing for livestock requires a thorough approach, so when building it with your own hands, you should definitely take into account some requirements:

- The location of the building is chosen taking into account the wind rose and the flow of spring waters.

- It is not advisable to place the future farm in close proximity to residential buildings or sources of drinking water: wells or boreholes.

- The material chosen for construction is high-quality, durable, has thermal insulation properties, and is environmentally friendly.

- When drawing up a project, it is advisable to take into account heating, for areas where it is very cold in winter, ventilation and lighting.

- Also, the size of the room must correspond to the needs of the animal: moving to food and resting places, it should not experience difficulties.

When drawing up a project, the size of the room is calculated taking into account the number of heads of cattle (see table 3.6), often a barn for calves is located in it. For example, according to the rules, 6 square meters are assumed per cow. When the uterus is kept with a calf, another 4 m is added.

Cow stall size chart

When keeping in stalls, the parameters of individual sections are provided, on average 125x260 cm.

Read also: Udder diseases in cows: their symptoms and treatment

The height requirements are not fundamental, but not less than 2.5 m. If the stalls are located on both sides, then the most acceptable passage width between them is one and a half meters.

The choice of foundation is a crucial moment; the strength and service life of the entire building depends on it. There are several types of it: tape, monolithic, columnar. The use is determined by the type of soil, the size of the barn, and the material of construction.

If you choose the option of a brick shed, then a monolithic base can support a heavy structure.

For a small wooden building, a foundation on pillars is quite suitable; it is much lighter and cheaper. It is important to take care of waterproofing and water drainage. This is achieved using a waterproofing slope, a layer of sand and crushed stone along the outer edge.

Heavy structures require a strong concrete foundation

Barn floor

It is often recommended to make a concrete floor in a barn; this material can withstand the weight of adult bulls, will not let rodents through, and will not absorb “odors” and moisture. But do not forget that this material is very cold, so it requires a thick bedding of straw. It will be more practical and much warmer if you lay special, hand-made wooden panels on the floor; they can be easily removed for cleaning and washing.

It is better to raise the floor above the level of the outer surface to create a slope. To drain waste, it is arranged with an inclination towards the liquid collector of approximately 2-3%. Too much slope can lead to leg disease or abortion in the cow.

When a cow farm is designed for a large number of animals, then a slurry collector is needed - this is a container of impressive size, 1.2 meters wide, and its depth is 80 cm. Manure flows down a chute, which is located at the back of each compartment; its sufficient depth is 10 cm, and the width is 20.

When the cow is kept on a bed of straw, there is no need for a slurry collector, and the cleaning process is noticeably simplified.

The floor in the barn is best made of concrete

A barn for a cow requires walls made of high-quality material. For a large building this could be brick or foam blocks. Wood is not suitable for a large room, since its construction will be very expensive, and it will wear out much faster than its brick counterpart.

For a small barn for several heads of bulls, wood is a good choice. It has good thermal insulation properties, the highest environmental characteristics, and it is much easier to repair a small building.

The room where the cows are located must be constantly provided with fresh air circulation. The most comfortable temperature in the barn in summer is 20 0 C. These indicators in the summer are achieved with the help of ventilation.

For this purpose, several ventilation holes are equipped; if necessary, they are closed. They are installed at a height of at least 2.5 m. For a small barn, you can build in a special pipe.

Windows are needed for natural light and additional ventilation. Their location from the floor is 1.2. And the size of the openings depends on the scale of the room: 1:10.

The walls in the barn should be made of high-quality brick or foam concrete

The roof is usually covered with slate, this material is the cheapest; sometimes for additional lighting in the southern regions it is made of polycarbonate.

It is desirable to have an attic in the barn. Firstly, this will prevent heat from escaping during the winter. Secondly, you can keep hay and other feed on it. In this case, it is more expedient to organize the power supply directly from above. If an attic space is not provided, then the roof will have to be additionally insulated.

It is most advantageous to cover the roof of a barn with slate

Corral for walking

An indispensable equipment of the barn is a paddock for walking, its place is located outside the barn. It is intended for the walking of cows and bulls, so its area is arranged based on this calculation. The minimum length of a walking path is usually about 500 m.

On one side, the pen is covered with a canopy so that the cows can hide from the scorching sun or rain.

It is fenced with a reliable fence so that the cows do not wander off, and a gate is installed in it.

Read also: Ayrshire breed

Feeders and drinkers

Proper equipment of drinking bowls and feeders will provide animals with free access to food and water. On a farm where stalls are arranged in 2 rows, they are equipped with feed containers outside, this makes it easier to ensure the supply of food. Their length is designed to cover the entire width of the stall. If they are placed near the wall, then moisture from the animals’ breath will settle on the food.

The shape of the feeder resembles an inverted trapezoid, which makes it easier for the animal to get to the food and for the owner to clean it. The back side is made 75 cm high, and the front side, located closer to the animal, is 30 cm. The width at the bottom is 40 cm, at the top it expands to 60 cm.

There are holes in the bottom to make cleaning easier. The bottom of the feeder is located at a distance of at least 7 cm from the floor. If they are wooden, then the requirement for them is a smooth surface so that the animal does not get hurt.

On a large farm, the feeders are arranged in two rows

You can make feed boxes with your own hands or buy them; now there is a large selection of reliable feeders made of synthetic materials that are durable, environmentally friendly, and easy to clean and handle. They are much more convenient to clean and disinfect.

The drinking bowl is located a little higher, in the far corner. So that the animal can drink at any time, it is better to make it automatic.

When equipping stalls for cows, it is important to take into account the breed and size of the animal. For example, for beef bulls and for an ordinary dairy cow, the sizes will differ significantly.

On a farm with a small number of heads, do-it-yourself stalls are made from wooden boards or metal pipes. Brickwork is also used, but it is difficult to move under changing conditions.

The purpose of the stall is to position the cow correctly, with her face toward the trough and her rear toward the gutter.

It should not be too narrow, but it should not be too spacious either, since the animal will constantly turn around in it, which will lead to excrement near the feeder. The material chosen is safe and does not absorb moisture. The width of the compartment is 125 cm, length 2 m 60 cm, sometimes increases to 3 m 30 cm.

The main purpose of the stall is to position the cows correctly

Features of deep litter

Calves are usually kept on deep straw bedding, as well as cows before calving. The advantages of such bedding are warmth and softness. Disadvantages: active proliferation of pathogenic bacteria. To avoid infections, “deep litter” preparations are used. The drug is used not only for bedding made of straw, but also sawdust. It increases the shelf life of the litter several times.

After using the drug, a straw bedding can last up to one and a half years, and a mixture of sawdust and straw can last up to two years.

In order to use the drug, the floor must be covered with a layer of bedding of at least 35 cm. Powder of the drug is poured onto the straw, which can be pre-mixed with flour or bran. This will speed up the growth of beneficial bacteria. Then the cows are released. After a few days, pour another 30-35 cm layer of straw and another portion of powder.

After one and a half to two years, the litter is completely replaced. Old bedding is a mixture of manure, compost and straw. It can be taken to fields and used for fertilizer.

Keeping calves

Calves of dairy breeds are kept separately from their mother, so the farm must have a room for calves; it will be equipped separately in the barn.

Usually these are cages or houses. The positive side of individual care is that it is much easier to look after each baby. And when he is weakened, there is no need to be afraid that he will be pushed away from the feeding trough by a stronger peer. The size of the cage is selected to allow for the unhindered movement of animals for the development of the musculoskeletal system.

Cows often give birth to offspring in winter, so during the cold period it is important to provide the young animals with comfortable conditions. It is now possible to purchase individual boxes for calves. They are made of light, light polyethylene; they look like a hollow cylinder, with an entrance on one side. Their advantage is that washing and disinfecting, moving from place to place is very simple, and such a “dome” can retain heat and create a feeling of protection for the baby. The calf will be able to eat food directly in it, since there is a compartment for hay and a feed dispenser. Such houses are very durable and can be used for more than one year.

Individual calf box

To prevent the calf from leaving the room, the entrance to the houses is half blocked with a mesh, and a bracket for the feeder and drinking bowl containers can be attached to the wall.

Making houses for calves

When there are a lot of calves and houses are too expensive to buy, you can make them yourself. Naturally, plastic is not suitable in this case; it can be replaced with a wooden board. You will need high-quality softwood timber, fastening material, tools, and a little effort.

First you need to make a drawing.

Then, in accordance with the drawing, the tree must be marked and the necessary fragments cut off.

They can be fastened dome-shaped or in the form of a rectangle. The height of such a structure should be suitable for human height, approximately 180 cm.

Read also: Vaginal prolapse in cows: etiology, treatment, Veterinary Service of the Vladimir Region

Housing for calves requires the presence of a floor. It is made from tongue-and-groove boards and covered with hay on top.

The outside of the houses can be covered with forcing.

Since it is located indoors, it does not require additional insulation.

But for especially cold days, it is good to hang a strong lamp in such a box, then the newborn calf will definitely not freeze.

A simple calf house can be made from straw bales.

For breeding bulls, you can purchase a mating pen; this device is convenient when the cow is small and the weight of the bull will not be felt as much by her. Do not forget about maintaining the sanitary condition of the barn; treating the walls with lime and disinfection are necessary measures for its normal functioning.

In order for the barn to meet all the necessary requirements, satisfy the needs of animals and contribute to their productivity, it is important to comply with all the conditions of phased construction. When choosing materials, take into account their quality and safety, and provide for all the nuances when planning the space. This is the key to the lion's share of success.

This is not rubber!!!

“Care” floor coverings are made from environmentally friendly polymer material EVA (Ethylene Vinyl Acetate). EVA polymer is non-toxic, environmentally friendly, and also has hypoallergenic and antibacterial properties. Children's toys are made from this material, which indicates that it meets high safety standards. Floor coverings, unlike rubber coverings, do not change properties due to temperature changes, do not have an unpleasant odor, do not stain, the mats are lightweight (only 11 kg), their installation does not require much time and special skills.What to make a floor for a cow in a barn from

When choosing a material for construction, you should pay attention to its ability to retain heat, absorb or repel moisture, and ability to withstand loads. Equally important is the raw material used in the manufacture of the material: how toxic it is, and whether its fumes will harm the cows.

Did you know? Cows are the second largest mammal in the world after humans. And in Australia there are 40% more cows than people.

The advantages of a wooden covering are its environmental friendliness and the fact that it retains heat well. Otherwise, wood is not recommended for flooring, since it quickly absorbs moisture and odors; this property accelerates the aging process of wood and its rotting.

The tree may not support the weight of the herd; in addition, dozens of hooves will leave indentations on it, and subsequently the animal may trip here and be injured. Wood is difficult to disinfect and clean from feces, so the material also loses in terms of barn hygiene.

It will also be useful for you to learn how to build a barn for cows with your own hands, how to make ventilation in it, how to make a stall and drinking bowls yourself.

Cement or concrete

There are conflicting opinions regarding concrete and cement:

- on the one hand, the material is durable and strong, does not allow moisture to pass through, and is easy to clean, wash, and disinfect;

- on the other hand, concrete is cold, such a floor will provoke diseases in animals, in particular, mastitis in heifers, reducing their productivity.

However, after weighing the pros and cons, most farmers use concrete. The lack of heat is compensated with the help of warm bedding, for example, livestock mats.

Burnt brick

Brick is made from clay, which is then fired for strength, producing hollow and solid bricks without voids.

Among the advantages of the material:

- environmental friendliness;

- sound insulation;

- thermal insulation;

- fire resistance;

- resistance to corrosion and fungi.

The main disadvantage is considered to be the high cost compared to other materials; in addition, brick is not able to withstand heavy loads. The hooves will leave cracks and gouges, which over time will begin to let in moisture. Brick is more suitable for the walls of the structure.

Livestock mats and mattresses

Special livestock mattresses for cows are manufactured using modern technologies. The thickness of the mattress is from two to six centimeters, and the width of one layer is from 120 to 180 cm. Mattresses can withstand not only the weight of an animal, but are also resistant to damage from sharp hooves. They are designed and created taking into account veterinary requirements, as well as the characteristics of keeping cattle.

Using livestock mattresses significantly reduces the chance of udder and hoof disease.

The coatings consist of two layers. The outer is hard, wear-resistant, waterproof and non-toxic. It is made of polypropylene fabric. A special pattern is applied to the surface of the layer, which prevents any slipping. Thanks to this pattern, any spreading material adheres well to the mattress. Polyurethane foam is used for the inner layer. This is an environmentally friendly material that is often used as a filler for ordinary mattresses. To prevent moisture from getting into the inner layer, it is covered with a film of durable polyethylene.

Livestock mattresses are quite easy to install. They are attached to the floors using edging beams. Mattresses remain durable and do not deform for several years.

Mat design

There are cheaper analogues of livestock sailors. They consist of a filler that provides elasticity and an outer layer made of special waterproof fabrics. Sand, finely chopped straw, pressed sawdust, and finely chopped car tires are most often used as filler.

Mats Care made in Russia

Mattresses with rubber filling are usually used in birth boxes. They are quite easy to use and make caring for animals easier. For greater comfort and warmth, a layer of sawdust or straw is placed on the mats.

Why do you need such a product?

In the process of raising animals indoors, large amounts of manure accumulate. It releases ammonia, which is a toxic gas. At high concentrations of this gas, livestock weight gain sharply decreases and the health of cattle deteriorates.

To reduce the negative effect, powerful ventilation systems must be installed in the barn. Aeration should occur at least 10 times within an hour. In winter, if such ventilation systems are available, the barn should be equipped with an additional heating system. All of these factors contribute to increased costs of pet ownership.

Another problem for many livestock farms is the need to regularly remove organic waste. This procedure must be performed at least in the morning and evening. And this implies costs that negatively affect the profitability of meat or dairy products.

If there is bedding, the requirements for cleaning the premises are significantly reduced. After cleaning the barn, air purity improves significantly. Installation of a ventilation system in this case is required to maintain optimal humidity levels. And this requires small amounts of electricity.

Taking into account the breed of animals, it is necessary to clean such bedding. This procedure is performed once a month or once every three months. Since there are absolutely no foreign odors, this product can be stored close to living quarters. The sale of such fertilizers can be carried out without prior preparation.

Important! Microorganisms are absolutely harmless to humans and animals. They do not provoke the development of allergic reactions and do not cause harm to the external environment.